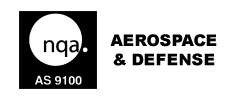

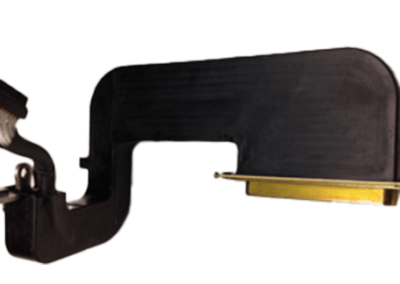

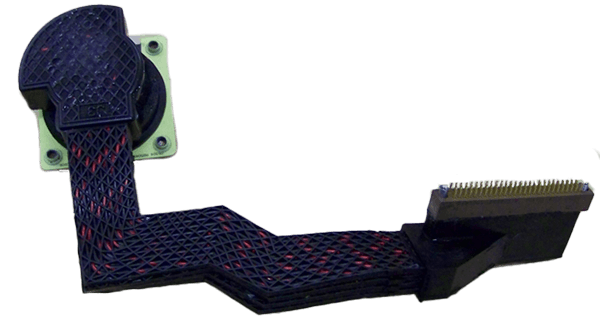

Over Molding

Midcon has 50 years’ experience cold molding and over-molding cable assemblies for Defense and Aerospace applications. We mold per MIL-M-24041 and have a proprietary quick set potting compound that can give significant cycle time advantages to customer. Midcon has an in-house machine shop that is staffed by tooling engineers with over 50 years of combined experience that can design and manufacture cold mold tooling for any application. Our tooling cost and lead times are the most competitive in the business and we pass those benefits to our customers.

Benefits-Low Pressure

-

Applications from commercial to military/defense applications including military ground based and air applications

-

Multiple applications from straight to angled to multiple breakout

-

Helps with routing of the cable assembly within an application

-

Multiple design options that include but are not limited to flexibility and routing of the assembly

-

Improves flexibility

-

Provides ruggedization of cable assembly

-

Increases life expectancy of cable assembly

-

Short curing timesProvides protection with cables exposed to environmental conditions

-

Provides protection against dust and or debris

-

Low pressure polyurethane molding that meets MIL-M-24041

-

High pressure injection molding

-

More cost effective than back shells, provides strain relief at the connector joint