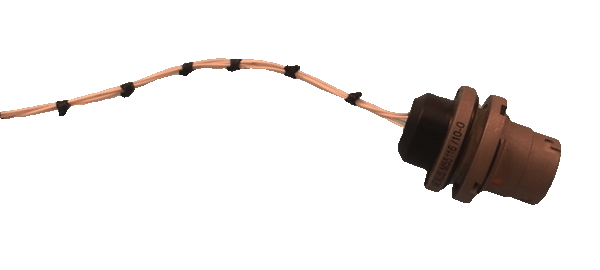

Low Temperature Molding

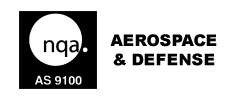

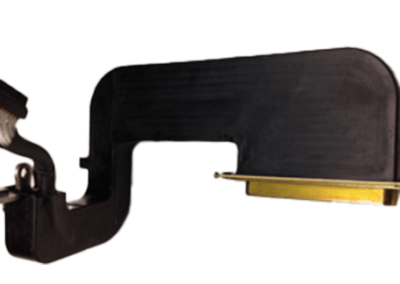

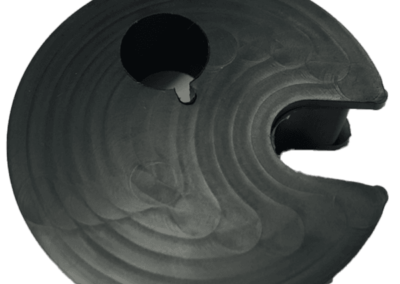

Midcon has 50 years’ experience cold molding and over-molding cable assemblies for Defense and Aerospace applications. We mold per MIL-M-24041 and have a proprietary quick set potting compound that can give significant cycle time advantages to customer. Midcon has an in-house machine shop that is staffed by tooling engineers with over 50 years of combined experience that can design and manufacture cold mold tooling for any application. Our tooling cost and lead times are the most competitive in the business and we pass those benefits to our customers.

Benefits-Polyurethane

- Extensive experience with many different compounds, including but limited to the industry standard MIL-M-24041.

- Short demold time with elevated temperature cure.

- Proprietary two-part, fast cure polyurethane allowing a demold time of just over 12 minutes.

- Highly flexible wire management designs to ease installation and allow dynamic movement.

- Low viscosity material with excellent dielectric resistance.

- Provides strain relief for increased life expectancy without the need for expensive metal backshells.

Benefits-Epoxy

- Experienced with multiple two-part epoxies including, but not limited to the Stycast family of compounds.

- Low viscosity material with excellent dielectric resistance.

- High hardness compound great for static installations.

- Outstanding thermal stability and chemical resistance for harsh environments.

- Provides strain relief for increased life expectancy without the need for expensive metal backshells.

- Short demold time with elevated temperature cure.

Benefits-Silicone

- Experienced with both one-part and two-part silicone compounds.

- Highly flexible wire management designs to ease installation and allow dynamic movement.

- Provides strain relief for increased life expectancy without the need for expensive metal backshells.

- Outstanding thermal stability and chemical resistance for harsh environments.